Master's project - Parallel Manipulators

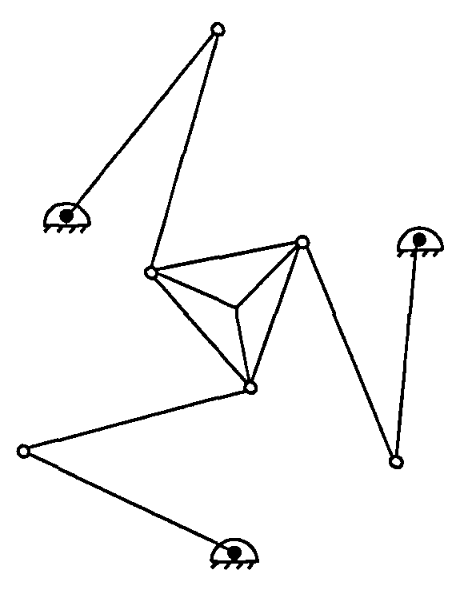

To obtain my master’s degree, I worked on the kinematics of parallel manipulators. Specificaly, I developed a novel method to determine the dexterous workspace of kinematically redundant parallel manipulators. So what is all that? Well, parallel manipulators are unlike most robots we see in the industry. Where industrial robots usually look somewhat like an arm, parallel robots use many arms, called kinematic chains to move an end-effector or tool. To illustrate this, refer to the next figure.

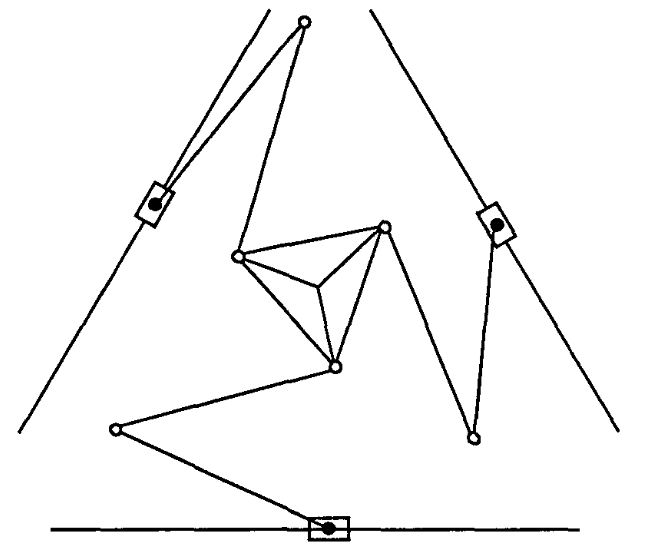

This figure shows a planar (2D) parallel manipulator of the type on which I worked during this project. We can see three kinematic chains (arms) working together to move a triangular platform. Now, kinematic redundancy can mean a few different things, but in our case it meant adding more joints to each chain, such as in the next figure.

In this case, we see that the base of the three chains have an extra joint: they can slide along an additional axis.

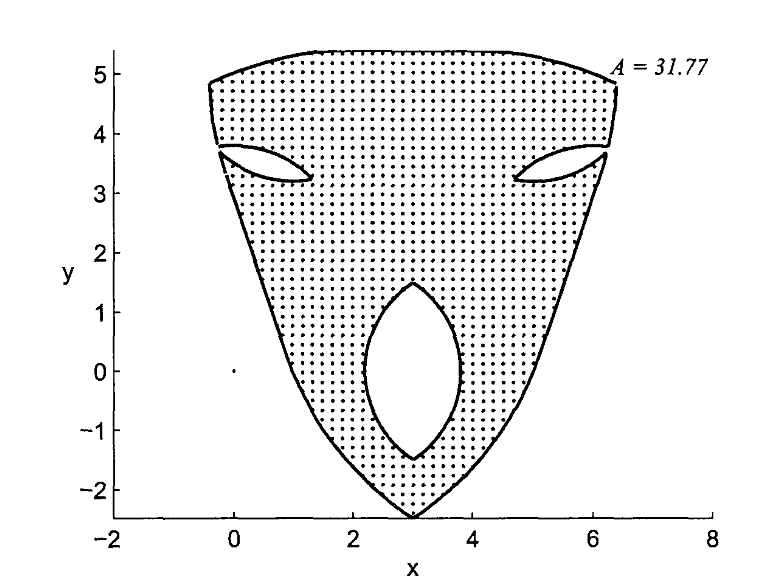

Finally, what is the dexterous workspace? First, the workspace of a robotic manipulator is the area (planar) or volume (3D) that the tool can reach. The dexterous workspace is the area or volume that the tool can reach in any orientation. For the manipulators shown in the figures above, this is the area where the tool can reach and rotate 360 degrees. Here is an example of what the dexterous workspace looks like:

The old way of determining the dexterous workspace was to sample a large number of points in a large region surounding the manipulator and testing to see if it lies in the space. The sum of all these points is therefore an approximation of the dexterous workspace. The new method, developed in this project, is a little more complicated, but it provides the exact geometric solution. The precision of the new method is therefore dictated by the floating point precision used in the computations and not the number of sampling points.

Expertise developed

- MATLAB ®

- Robot kinematics and dynamics

- Technical and scientific writing

Publications

This project resulted in one thesis, three conference papers and three journal papers:

Thesis

- Gallant, A. (2011). Détermination de l’espace dextre des manipulateurs parallèles plans avec redondance cinématique. (pdf, Google Scholar)

Journal Papers

- Gallant, A., Boudreau, R. and Gallant, M. (2012). Dexterous Workspace of n-PRRR Planar Parallel Manipulators. ASME Journal of Mechanisms and Robotics. (Google Scholar)

- Gallant, A., Boudreau, R. and Gallant, M. (2012). Geometric determination of the dexterous workspace of n-RRRR and n-RRPR manipulators. Mechanism and Machine Theory. (pdf, Google Scholar)

- Gallant, A., Boudreau, R. and Gallant, M. (2009). Dexterous Workspace of a 3-PRRR Kinematically Redundant Planar Parallel Manipulator. Transactions of the Canadian society for mechanical engineering. (pdf, Google Scholar)

Conference Papers

- Gallant, A., Boudreau, R. and Gallant, M. (2011). Dexterous Workspace of n-RRRR and n-RRPR Manipulators. Transactions of the 2011 CCToMM M3 Symposium. (pdf, Google Scholar)

- Gallant, A., Boudreau, R. and Gallant, M. (2010). Dexterous Workspace of N-PRRR Planar Parallel Manipulators. Proceedings of the ASME 2010 IDETC (pdf, Google Scholar)

- Gallant, A., Boudreau, R. and Gallant, M. (2009). Dexterous workspace of a general geometry 3-PRRR kinematically redundant planar parallel manipulator. Transactions of the 2009 CCToMM M3 Symposium. (pdf, Google Scholar)